AODD Pumps - Routine Maintenance Guide

Routine AODD pump maintenance not only extends the life of your system, but also reduces operating costs. Addressing preventative care can help you resolve existing problems, prevent future issues, safety hazards and potential pump failure.

Unplanned downtime leads to lost revenue and should be avoided at all costs.

Follow these 4 inspection steps for routine AODD pump maintenance to ensure your system stays up and pumping!

1) Leak Detection

Checking for leaks should be a priority in pump maintenance as it can prevent downtime, lost revenue and safety hazards.

Pumping Solutions highly recommends advanced leak detection options (electronic or mechanical) for hazardous & costly fluid applications. Contact us to explore both options and determine the best fit for your application.

2) Filter & Regulate Compressed Air

You wouldn’t put pancake syrup in your car engine. Don’t put dirty air in your air operated pump! Always use good, clean, dry air to run your pump and keep hose fittings clear of dust and grime. Dirty, moist and inefficient airflow can limit the lifespan of your AODD pump. Installing an air filter/regulator unit will clean the air and ensure you use the correct amount of pressure for your pump and application.

3) Pulsation Dampeners / Surge Suppressors

The strokes from AODD pumps can naturally produce pulsation and hydraulic shocks that may damage the fluid transfer system. Surge suppressors can smooth product flow and reduce the “hammer” effect caused by these shocks. Browse all of our easy to install suppressors or dampeners to ultimately increase the life of your AODD pump!

4) Inspect Mechanical Parts & Seals

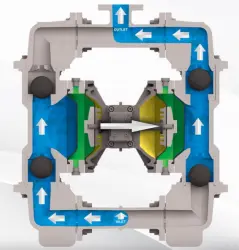

Take full advantage of the simplicity of AODD pumps to routinely disassemble and inspect their interior parts. Most parts are easy to replace, spotting the first signs of wear or decay could help you avoid more severe and expensive damages. Visible signs of deterioration can be detected early on in parts like diaphragms, valve balls and seats as well as hoses and seals.

?Order a repair kit from our website for your AODD pump! Each Air & Liquid End Repair Kit comes with the common wear items pre-packaged and ready for quick installation.

?Pumping Solutions offers Pump Repair!

Contact us and we’d be happy to help.

To avoid the loss of revenue from downtime, we highly recommend having a spare pump on the shelf. This may be an investment up front, but when you calculate the loss of production and the labor hours involved in not having a functioning pump, the ROI will pay for itself the first time you have an unexpected failure.

Be prepared and Keep on Pumping!